Patented technology

Our team was able to combine incompatible materials into a single whole.

Thousands of hours of manual work

Hundreds of failed attempts

Dozens of specialists

One technology

Projecting

Creating a sketch, 2D model and layout.

– It is important to consider technical limitations. The minimum diameter of a diamond-fired cutter for stone is 4 mm, which seriously complicates the creation of a model

Laser cutting of metal

Sheet metal 1.5 mm thick is cut into the required parts

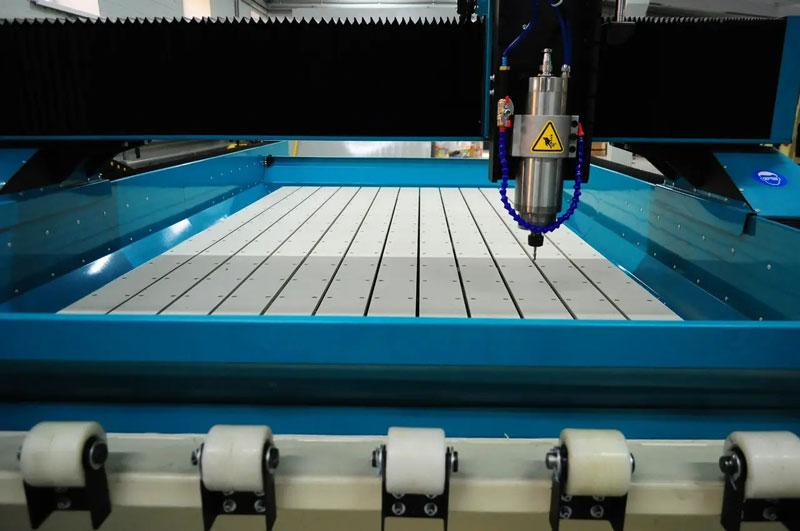

CNC milling

Milling grooves for inlay. The height tolerance for inlay is less than 0.1 mm. Due to the unevenness of the stone, the height measurement is carried out separately for each metal part.

Manual grinding

After manual grinding, it is impossible to feel the difference in height between the metal and the stone. The difficulty lies in controlling the height of the polishing disc, because natural stone is not homogeneous due to its natural features.

Manual polishing

Hand polishing gives the metal a mirror surface while preserving the color and texture of the stone. The peculiarity of this stage is the heating of the metal, the master carefully monitors the temperature to avoid defects.

Jewelry polishing

Each metal element is polished by hand by a specially trained jeweler. After that, there are no scratches on the metal.

The last stage gives the product an amazing look and takes from several hours to a week (depending on the complexity of the product).

Projecting

Laser cutting of metal

CNC milling

Manual grinding and polishing